Apex Chassis

HD Front Upper Ball Joint Fits: 06-08 RAM 1500 03-21 RAM 2500/3500

HD Front Upper Ball Joint Fits: 06-08 RAM 1500 03-21 RAM 2500/3500

Couldn't load pickup availability

Ram Super HD Front Upper Ball Joint For 06-08 RAM 1500 03-21 RAM 2500/3500

Apex Chassis

What It Fits:

Dodge RAM 1500 (2006-2008) 4WD

Dodge RAM 2500 (2003-2006) 4WD

Dodge RAM 2500 (2007-2010) 2WD or 4WD

Dodge RAM 3500 (2003-2010) 2WD or 4WD

Dodge RAM (2011-2013) 4WD

Dodge RAM 2500 (2014-2021) 2WD or 4WD

Dodge RAM 3500 (2011-2021) 2WD or 4WD

- E-Coat Finish: Durable e-coat treatment.

- Grade 8 - Class 10.9 Hardware: Superior tensile strength

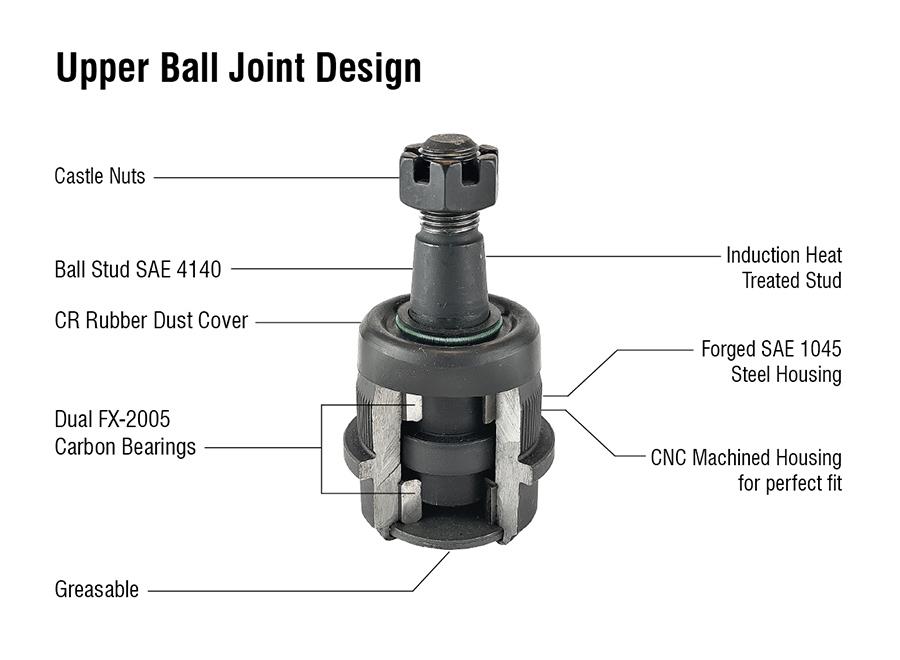

- Castle Nut: Industry standard where high vibration loads occur.

- SAE 1045 Solid Steel Forged Housing: This is unequivocally the best carbon alloy steel for this application.

- Knurled Housings: The preferred design for aftermarket installations.

- CNC Machined Housing: Make our parts and bearings dimensionally perfect, eliminating any die wear issues.

- Carbon Bearing Design: Used mainly in Jeep and upper ball joints is the solver of all things wobbly. Like all of our product

- SAE 4140 hot forged Chromoly Ball Studs: For the strongest possible metallurgy.

- Plunger Design Stud: Unique to Jeep and , allows up and down movement with no side-to-side movement.

- Induction Heat Treated Ball Studs: Provides a very precise heat treatment to the exact depth and location we want it.

- Rolled Threads: Are made by pressing the shape of the threads into the ball stud instead of cutting. This strengthens the threads instead of weakening them and allows for easy movement of hardware. This ain't no Ikea furniture!

- Step Threads: allows for very easy movement of hardware on install and superior holding when torqued (installer choice).

- CR Rubber Boots: The most durable material for undecar applications. Resistant to deterioration from road level ozone, oil/gas/engine fluids and extreme heat or cold.

- Internal Seal Boot: The boot is coined onto the ball joint, for superior sealing against contaminants.

- Pre threaded Zerk Housing: If you have ever installed a MOOG Ball Joint without a pre-threaded zerk fitting you will understand what a simple but great feature this is. Another installer fav.

- Greaseable: Because it should be.

- Pre-Greased: Just in case you forget, we have you covered.

- Zerk Fittings: Included for every application.

About APEX Chassis

At APEX, we Design, Engineer and Manufacture all of our products to our exact specifications. If it says APEX on it, from start to finish it is our product. As a family, we have been designing and building steering and suspension products for over 30 years.

APEX Steering Components

Many "steering" companies make tubes and then outsource the most complicated and important part of the system, the rod ends. At APEX, every component in your steering system is designed, engineered and manufactured by us to work together for the best possible system.

In our steering systems we also ensure that all the geometry is built into our forged steel ends, so you will never see bends in the tubes. Bends in tubes are used as an inexpensive way to re-purpose straight tie rod ends when a custom engineered off-set tie rod should be used.

APEX Bearings & Joints

The bearing designs that we use are individually tailored to each part based on application and load. Our ball joints are the go to ball joint for many podium finishers in both NORRA 1000 style and Ultra 4 style racing.

We also keep our designs simple for easy install and increased durability. Sorry, you just can’t build a durable, rebuildable ball joint. And we think you want to spend your time wheeling, so nothing adjustable that you have to monitor or maintain. Just an extremely robust product at an affordable price.

SKU:BJ130-JJSP

Share